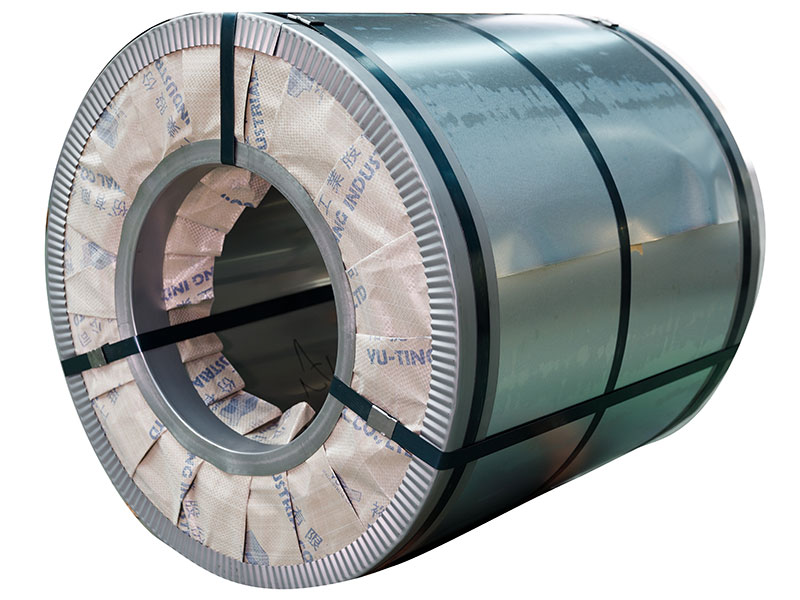

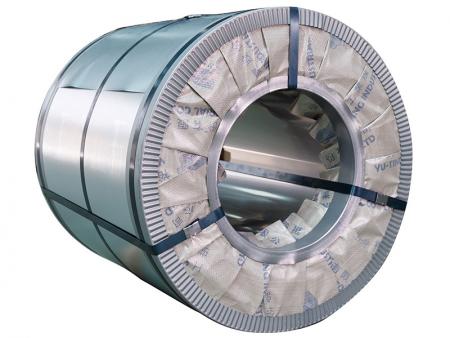

AISI 316L Stainless Steel Coil

AISI 316L

AISI 316L Stainless steel coil contains Min. 10% of nickel and 2% of molybdenum to increase pitting resistance. Under highly corrosion environment such as chemical factories / costal area, AISI 316L has better performance than AISI 304. Our product certified by RoHS / REAH, EN and ASTM standards. We guarantee AISI 316L contain sufficient chemical compositions according to above specifications.

AISI 316L is low carbon contained material. The carbon content is below 0.03%, so it will reduce carbide precipitate (sensitization) and result in better intergranular corrosion ability. The product is suitable for chemical, petrochemical industry or heat treatment component.

YU-TING also provides 316L-4 (SUS 316L) stainless steel coil which contains Min. 12% of nickel more and 2.5% of molybdenum.

Specification

01. Steel Grade: AISI 316L

02. Surface Finish: NO.1 / 2D / 2B / BA / NO.4 / HL

03. Thickness: 0.3mm – 3.0mm

04. Width: 1000 / 1219 / 1250

05. Coil Diameter: 508mm / 610mm

06. Surface Protection:

• Paper Interleaved

• Regular PE Film (80 ~ 100μ)

• Co2 Laser PE Film (100μ)

• Fiber Laser PE Film (100μ)

• Deep Drawing Film (60μ)

• Low tack PE Film (50μ)

| Grade | Standard | Chemical Composition | Y.S. | T.S. | E.L. | HRB | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ni | Cr | Mo | Mn | Si | C | N | P | S | (N/mm²) | (N/mm²) | % | |||

| 316L | ASTM A240 | 10.0 ~ 14.0 | 16.0 ~ 18.0 | 2.0 ~ 3.0 | ≦ 2.0 | ≦ 0.75 | ≦ 0.030 | ≦ 0.10 | ≦ 0.045 | ≦ 0.015 | ≧ 170 | ≧ 485 | ≧ 40 | ≦ 90 |

- Gallerys

English

English